Becoming an expert wine cellar builder requires that you fully understand how to insulate a space for the specific requirements of temperature and humidity climate control. US Cellar Systems is an expert in wine storage construction. When building a custom cellar, many of our clients consult with our experts to help them to understand exactly how to accurately complete the insulation phase of the construction process.

We recently conducted our first Custom Wine Cellars 101 on this topic, because of its importance. There are three types of custom wine cellar insulation. A wine cellar builder should be trained in the proper installation of all three of these insulation types.

Three Methods of Insulating a Custom Wine Cellar

Custom cellars are among the best places to store wines. Many factors contribute to the effectiveness of a wine cellar in providing its stock with the right storage conditions. One of those variables is a properly installed insulation system. These are the three most popular methods of insulating a custom wine cellar:

According to wine storage specialists, R-13 is the minimum required value of insulation for custom wine cellars. Fiberglass batts can adequately provide storage rooms with this.

1. Fiberglass Batt Insulation (GOOD CHOICE!)

Wine storage experts strongly recommend that cellars should have a minimum of R-13 insulation. This value can be adequately provided by fiberglass batts. If you decide to use this material for your custom cellar, make sure that a 6 mil plastic vapor barrier is applied to the warm side of the walls.

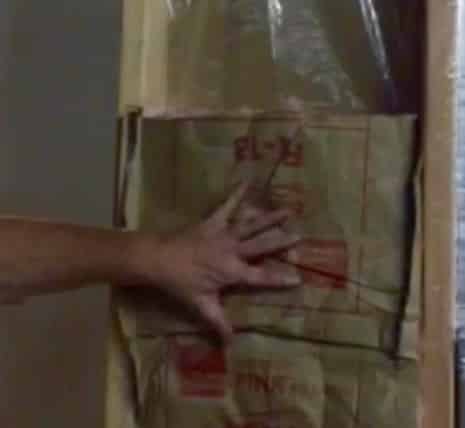

Some wine cellar builders wrap the entire interior of the walls and leave the plastic sheeting loose in the stud cavity so that the fiberglass insulation can be placed between each stud. Other contractors roll in the batting in between the stud cavities, and when this is finished, the whole wine storage structure is wrapped with plastic sheeting. It is important to remember that all of the room’s walls, ceiling, and floor should be wrapped in plastic sheets to create an effective vapor barrier.

Plastic sheeting is a material that is used by wine cellar builders to create an effective vapor barrier. This must be used if you’re insulating with fiberglass batts for your custom cellar insulation. A plastic vapor barrier is also necessary for rigid foam board insulation.

Fiberglass batts are the least expensive type of insulation for wine cellars. However, they are often poorly installed. If there are small gaps, the efficiency of the insulation is reduced by 25 percent. Contact a professional wine cellar builder to make sure that your fiberglass batts are correctly set up.

Questions about wine cellar insulation or other construction issues? CLICK HERE!

2. Rigid Foam Board Insulation (BETTER OPTION!)

Polystyrene, also known as rigid foam, is another common type of material used for insulating custom wine cellars. If you’re going to use a rigid foam board to insulate your wine storage space, you need to apply a plastic vapor barrier as well. Two layers of rigid foam panels that are both an inch and a half thick will provide your wine storage room with R-19 insulation.

A rigid foam board is a good choice for custom wine cellar insulation. It is cost-effective and easy to install. Make sure that you apply a plastic vapor barrier to the walls, ceiling, and floor of your wine storage room if you plan to use this insulation material.

Besides being cost-efficient, rigid foam insulation panels are a popular choice because they are easy to install. However, the disadvantage of using this material is if you have wiring, conduit, or any type of piping that needs to pass through the wine cellar wall. All pipes and wires need to be wrapped in rigid foam. Another option is to cut the insulation board and place it around the wiring, conduit, and piping. Then, have the gaps filled with spray foam.

3. Polyurethane Spray Foam Insulation (BEST TYPE!)

Closed-cell spray foam is the best type of insulation for custom wine cellars. A 3-inch application of this material will give your storage room R-19 insulation. The advantage of using polyurethane is that when it skims over, it forms its vapor barrier. There is no need to install plastic sheeting! Spray foam expands and fills all the cracks and crevices leaving no gaps. If there is any wiring, conduit, or piping that goes through the wall, spray foam creates a tight seal around it. There is absolutely no potential for vapor to penetrate the material.

Polyurethane is the best type of insulation for custom wine cellars. You need to have a spray foam expert apply the material to the walls of your storage room to make sure that it is installed properly. Correctly applied spray foam ensures that there are no areas for vapor to penetrate through.

Many custom wine cellar owners opt to use polyurethane to effectively insulate their wine storage structure. Become an expert in this very specialized niche construction market.

Want more information about wine cellar construction? Call +1 (562) 513-3017

Hire a Wine Cellar Construction Expert

US Cellar Systems is a refrigeration manufacturer with many years of experience building cooling units for wine cellars. Our customer service team of technicians is knowledgeable about the construction process of building wine cellars and installing the best cooling system for any space. Our contractor clients regularly call us with every sort of question about wine cellar refrigeration and construction. Watch Custom Wine Cellars 101 for regular monthly updates.